Two national facilities are better than one

A collaborative effort between ISIS Neutron and Muon Source and Diamond Light Source (two national facilities at Harwell Campus) have achieved a research first after the two facilities ran an experiment simultaneously using a joint AI platform.

A robotic sample preparation platform, driven by artificial intelligence (AI), was used to undertake simultaneous experiments at both ISIS and Diamond Light Source. While collaborative research between these two science facilities is common, this particular experiment has pushed new boundaries with the experiments being performed at the same time on identical robotic set-ups which were in direct communication with each other.

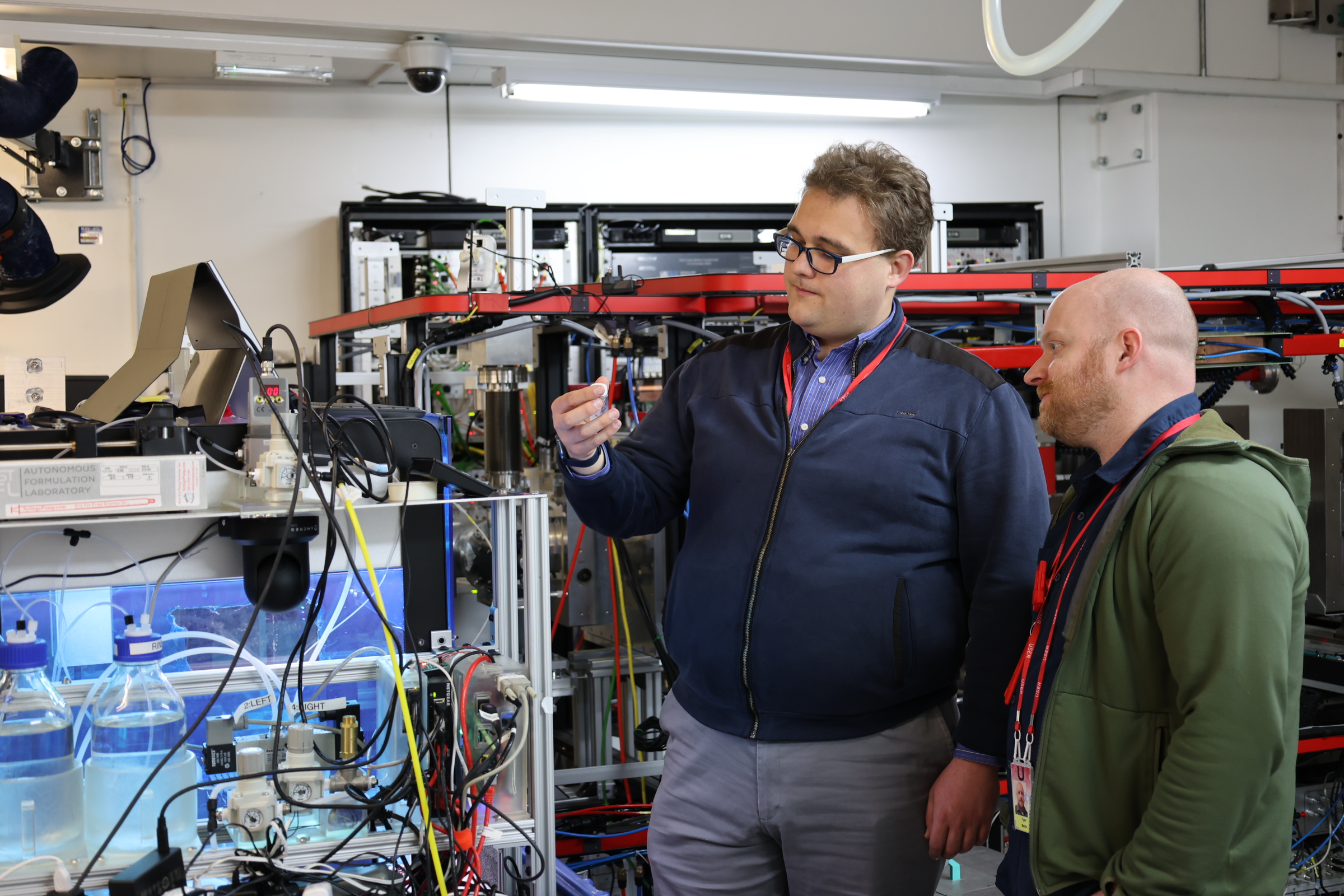

The simultaneous experiment was driven by two Automated Formulation Laboratories (AFLs), operated autonomously on Diamond’s I22 and ISIS’s Larmor small angle scattering beamlines.

Dr Gregory Smith, from ISIS, said, “We have discussed using the autonomous formulation laboratory for experiments at ISIS for many years, and it was only recently that we considered the idea of running neutron and X-ray measurements in parallel at ISIS and Diamond. Getting one piece of bespoke equipment on site to run an experiment is challenging enough, but it took great effort from many staff here at RAL, from support staff to scientists to engineers, to manage this. I was pleased to finally manage to get the AFLs here and use them as intended, and the exciting results produced by the NIST team justified all this work, resulting in a truly unique experiment.”

The experiment investigated paint formulations, making use of small angle scattering to determine properties of the system. The AFL machines, one red and one blue, were linked together across computer networks and worked concurrently, capturing multiple modalities of the formulations synthesised.

The project had two objectives; the researchers from NIST were testing the AI and robotic elements of the machines, whilst also working on an industrially relevant question – in this case “what is the optimal formulation of a given paint system?”

By using both small angle X-ray scattering (SAXS) at the I22 beamline and small angle neutron scattering (SANS) at Larmor, pictured, right, the experiment proved more effective in both the utilisation of beamtime as well as the quality of data collection. SAXS data can be collected more quickly than SANS data, which allowed the experimental team to rule out formulations that weren’t of interest. This allowed a more complete dataset from the significant formulations in a shorter amount of time, as the team could gather insights from the different parts of the system with each technique. Diamond and ISIS offered the unique opportunity for both formulation labs to work in unison at the neutron and X-ray facilities, a situation that is currently only possible in two locations in the world.

Tim Snow, principal software scientist working on Diamond’s I22 beamline, said “It is a really good example of both facilities working together to exploit our unique capabilities, acquiring the best data for our users.”

The robotic element of the AFL prepares liquid mixtures via pipetting and transfer those mixtures to a measurement cell. Following a SANS or SAXS experiment, the data is analysed by an AI software algorithm. The AI algorithm looks at the collected data to work out what mixture to make next and subsequently what scan to conduct next.

Dr Nick Terrill, principal beamline scientist on Diamond’s I22 beamline noted that “This is a great experiment, and example of coinvestigation across Larmor and I22. Applying recently developed AI to explore new research techniques opens up the potential for exciting new experiments in combinatorial chemistry and materials science.”

Dr Robert Dalgliesh, from ISIS, continued; “There is a long history of the small-angle scattering community using both X-ray and neutron scattering to understand complex multi-component formulation problems in collaboration with industry. The development of the AFL has shown us the potential for new ways of working and should hopefully be a stepping stone towards the technologies that will need to continue to develop as we look towards the construction of ISIS-II and Diamond-II. Working with the team from NIST to enable this experiment has been a lot of fun and has also highlighted the need to continue to strengthen collaborations between ISIS and Diamond.”

While this recent experiment was focused on paint, the portable formulation laboratories can be used in a huge range of products involving soft materials. These multi-component materials are present in industry but also in everyday life. Products like vaccines, fuels and shampoos are formulated with multiple components, sometimes even hundreds. If one part of a formulation needs replacing or changing, this can cause complex structural changes in the formulation that affect the efficacy, stability and processability of the product. The rapid data collection that can be performed by the AFL at facilities like Diamond and ISIS maps the potential changes and remedies to any formulation alteration.

While the AFLs collect and analyse the results, experiments like this are only possible at facilities like Diamond and ISIS where scattering techniques are openly available to users with exciting ideas from anywhere in the world.

Tim Snow concludes; “This set-up, allowing each machine the opportunity to learn from the other in real time, has meant that the two beamlines and facilities are truly working in concert.”